Part 1: Wheel Line Cider.

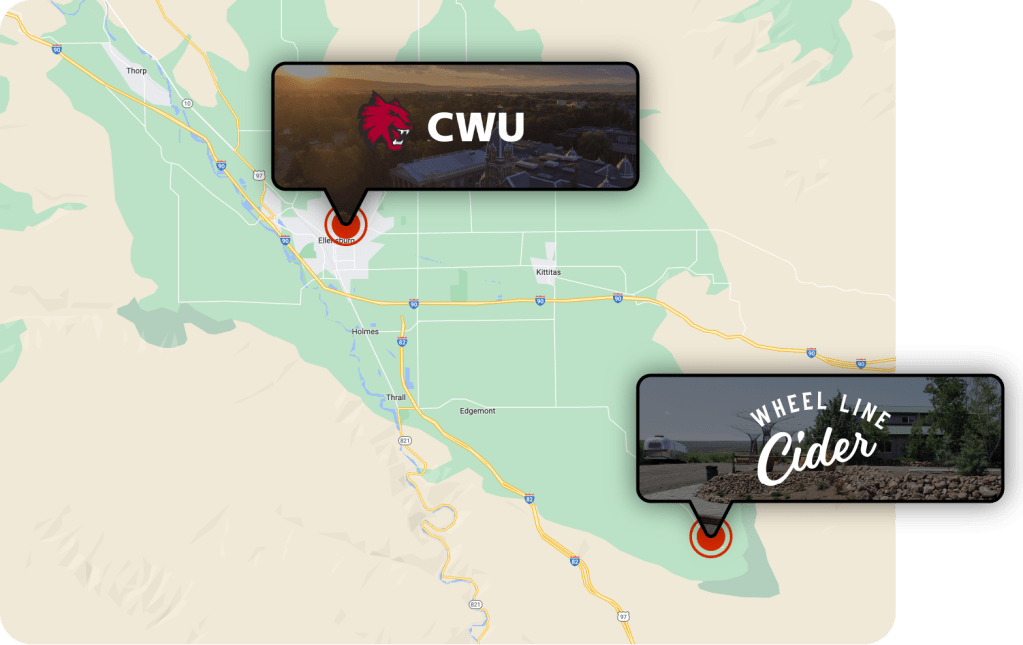

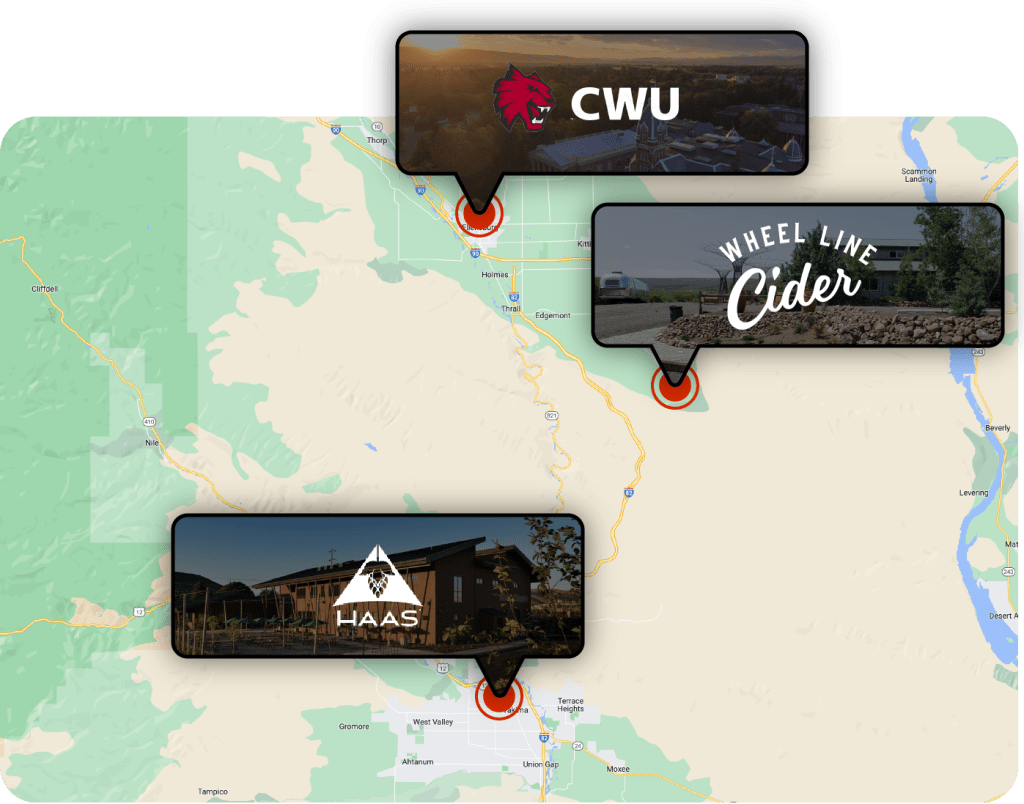

If you navigate the winding, rolling roads stretched across the shark’s-tooth wedge of fertile soil spanning the southern edge of Kittitas county, you’ll eventually find, tucked deep in Badger Pocket, Wheel Line Cider. Housed in a retrofitted barn bursting with fermentation essentials and overlooking sleepy farmland striped with the titular wheel line equipment, the humble cidery thrives on the fruits of the local Eastern Washington community.

Head Cidermaker Nate Lambert, facing a throng of students, gestures in all directions at the orchards “just down the road” who contribute to the creation and craft of their artisanal beverages. Rows of heritage apples line today’s classroom as we listen to him talk, describing the delicate process of avoiding pests, blights, and other hazards, the challenges of finding harvesting labor, and how to tell when it’s the ideal moment to pluck the fruit from the tree, bursting with the right stuff to create the perfect cider.

It’s a unique experience to be able to bite into an apple, mouth full of tannins and sugar, and be able to ask a cidermaker questions about how the process of growing, harvesting, processing, fermenting, and serving a cider works. Nate knows his craft well, and as the head of a small operation he experiences every aspect of the enterprise. He describes details ranging from the minutiae of the genetics of a tiny apple seed to the art of judging ripeness by taste, feel, and a sense that can only be earned by experience.

We’re ushered away from the Dabinett, the Manchurian Crab, the Somerset Redstreak, and the rest of the apple varietals and into the innards of processing and fermentation. Surrounded by towering polished steel, the fermentation tanks that contain the slowly evolving fruit juice, Nate takes us through a day-in-the-life of transforming the fruit of an apple into the beverage of cider. Through careful attention to chemical attributes, a suite of specialized equipment, and patience, the final product is gently crafted

Finally, after hours of anticipation, we get to taste the ciders and juices having observed every detail of their formation. Small, plastic cups are filled with a range of options from unfermented, fresh-pressed nectars, to dry ciders, to spirited concoctions. As CWU students we have the ability to peek under the hood and gain a unique insight into the cider making process. The transformation of the humble apple, pear, or other fruit into a finely crafted beverage takes skill, time, resources, knowledge, scientific acumen, and the labor of love, and it was a privilege to share the experience with Nate and Wheel Line Cider.

Part 2: HAAS

Departing the dreamy countryside cidery we made the journey across the swelling desert and to the nearby city of Yakima, a pilgrimage to the hop mecca of Washington. The vast majority of the hops grown in the US are grown right here in Yakima Valley, and a good portion of that volume passes through the doors of HAAS to be processed into various products before being delivered around the world for brewing and other applications. In contrast to Wheel Line Cider, HAAS is a vast campus dotted with office buildings, soaring industrial machinery, warehouses, and the bustling activity of hi-vis workers.

Donning protective equipment of our own we were taken from building to building, inspecting the inner workings of hop processing in all of its forms. HAAS is home to state of the art equipment and techniques for not just turning raw hop ingredients into refined products like pellets, extracts, and oils, but also for running rigorous scientific tests and studies on the hop they handle and develop, and a nano-brewery where they can explore new hop flavors and test innovative hop products.

Permeating every moment of the visit is the rich, resinous scent of concentrated hop aroma. Being on HAAS’s campus is to be constantly surrounded by the plant that imparts so many special traits into the beverages we love to enjoy. At the time of our visit harvest season was drawing near its end, so the factory was running non-stop to handle the immense throughput required to make the best use of that year’s crop. We wove our way through the rush, dodging forklifts hoisting hundreds of pounds of fresh hops, through water-tower-like, brushed steel vessels of extract, and through processing machinery the size of a small apartment building.

From the humming industrial floor, to the studious laboratory, to the lively taproom, HAAS personifies excellence in hop innovation, technology and passion. After a long day of touring Wheel Line Cider and HAAS it was a relief to sit in their courtyard, relax with some tastings from their nano-brewery, and conversation about the experience we had, and the world of hops and beer. It was an incredible and enlightening opportunity for us CWU brewing students to participate in, and we thank the kind folks at HAAS for taking time to show us their work.