The traditional process of creating lager beer has been unchanged for hundreds of years. This technique involves fermenting at cooler than ale temperatures (50 degrees F instead of 68 degrees F) and storing the beer cold for months before consuming. While this process may take more patience, it produces an outstanding product, and that is why brewers today still follow this tradition when making lagers. In current commercial brewing, time is money. Many people cannot afford to wait 8-12 weeks to sell their product. In addition to that long wait, there is one less vessel available for other beers being brewed.

There is another way to expedite this process, but it goes against tradition. This involves fermenting a lager beer at ale temperatures. Many have believed that fermenting this style any warmer than 55 degrees F with lager yeast would produce esters (fruity aromas produced in beer fermentation). Even when fermenting ales at warmer temperatures (65 degrees F), a 10 degree rise in temperature can produce noticeably more aromatic compounds. I wanted to test this idea out and see if there is a perceivable difference between a warm fermented lager and a cool fermented lager.

For this experiment I planned to brew two batches of pale lager, one fermented cool and lagered for at least a month, and the other fermented 11 degrees warmer and lagered for 1 week. These were not one batch of beer split into two fermenters, rather they were staggered 2 weeks apart from each other. I decided to perform the experiment this way in order to see if one could brew a lager beer in 2-4 weeks as compared to 8-12 weeks.

I wrote my recipe with the style Helles in mind. Disclaimer: I made a mistake when gathering supplies for my second iteration of this recipe, and I had forgotten the hops at CWU so I had to improvise with what I had at home.

Recipe Details

| Batch Size | Boil Time | IBU | SRM | EST. OG | EST. FG | ABV |

| 20.82 L | 60 Min | 22 | 4.2 | 1.048 | 1.010 | 5.0% |

| Actuals | Cool | 1.052 | 1.020 | 4.2% | ||

| Warm | 1.048 | 1.015 | 4.3% |

Fermentables

| Name | Amount | % |

| Weyermann Pilsner Malt | 8 lb 4.6 oz | 86% |

| Briess Bonlander Munich Malt | 15.4 oz | 10% |

| BestMalz Acidulated Malt | 4.6 oz | 3% |

| Weyermann Melanoidin Malt | 1.5 oz | 1% |

Hops

Cool Fermented Batch:

| Name | Amount | Time | Use | Form | Alpha |

| Liberty | 33 g | 60 min | Boil | Pellet | 4.0% |

| Liberty | 20 g | 30 min | Boil | Pellet | 4.0% |

| Liberty | 20 g | 20 min | Hopstand 165 degrees F | Pellet | 4.0% |

Warm Fermented Batch:

| Name | Amount | Time | Use | Form | Alpha |

| Zeus | 10 g | 60 min | Boil | Pellet | 14.9% |

| Willamette | 28 g | 15 min | Boil | Pellet | 3.2 % |

Yeast

| Name | Lab | EST. Attenuation | Temperature |

| M84 Bohemian Lager | Mangrove Jack’s | 72-76% | 50F – 59F |

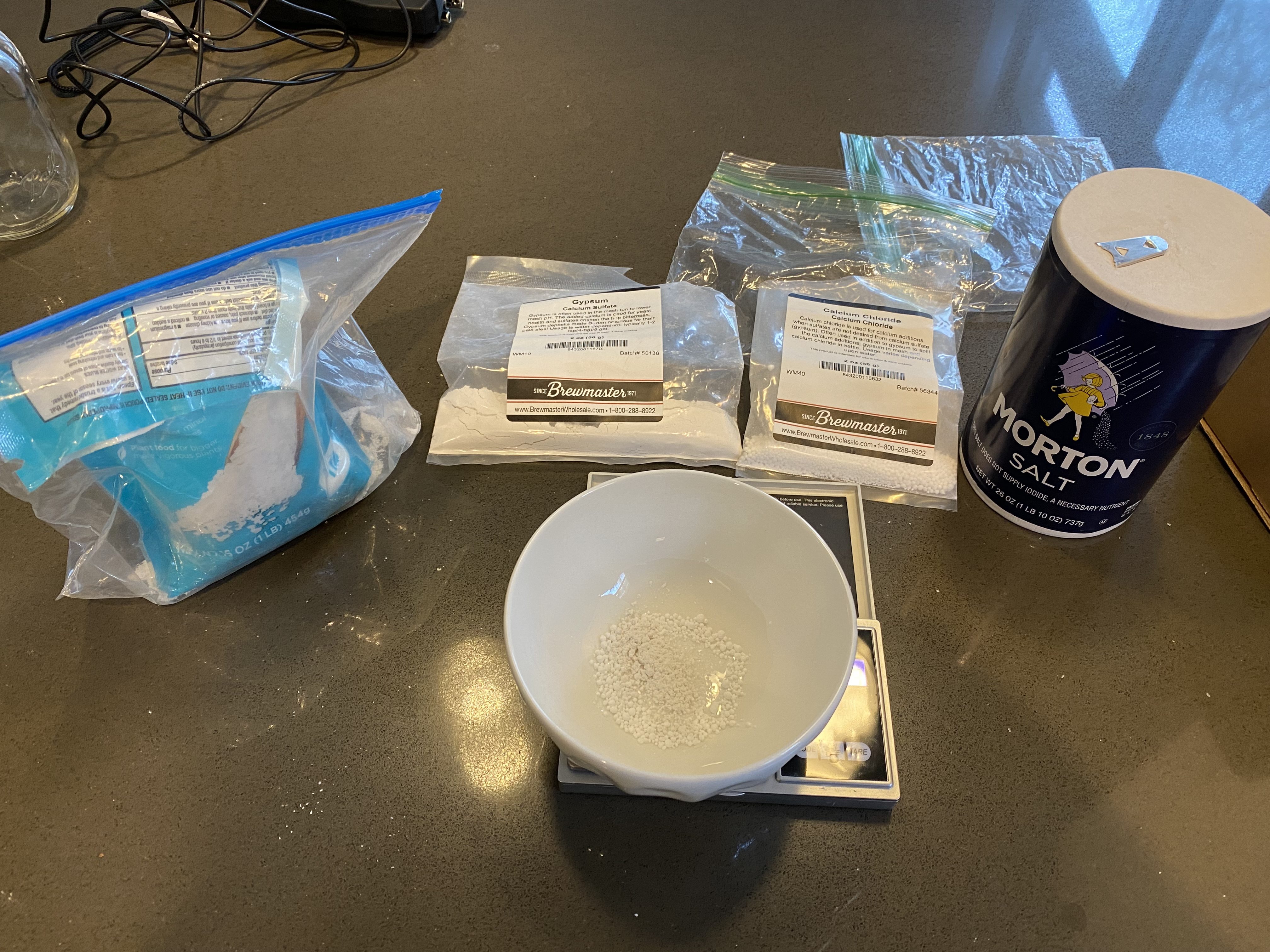

Water Profile

| Ca | Mg | Na | Cl | SO4 | HCO |

| 61 | 10 | 13 | 108 | 66 | 0 |

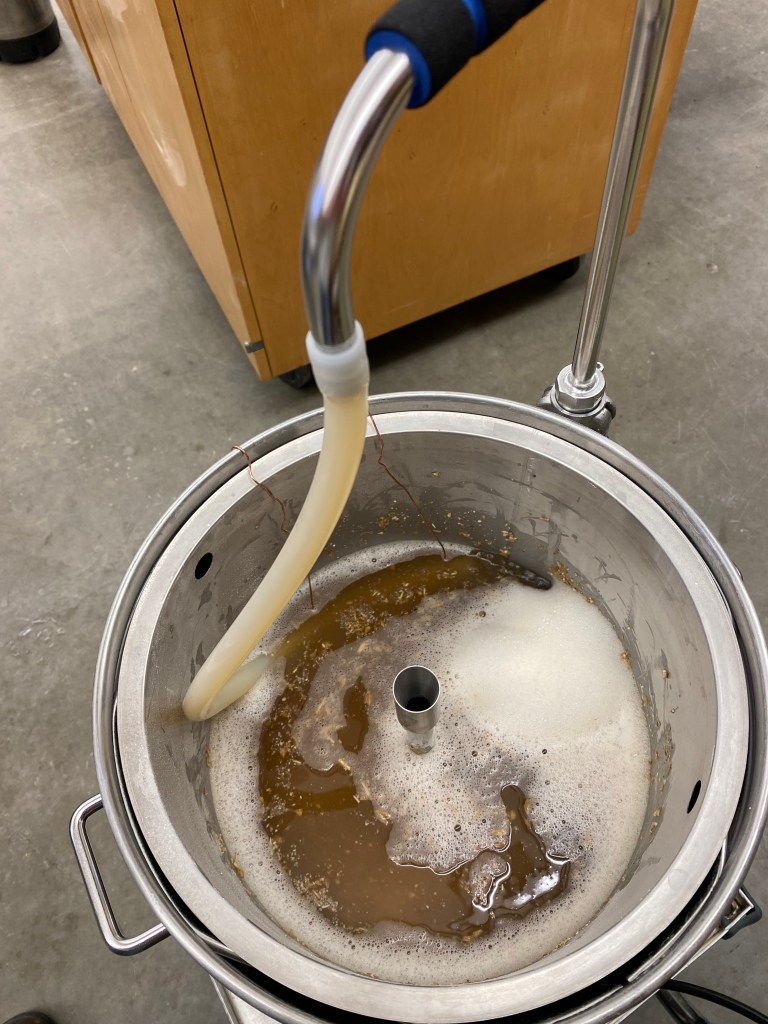

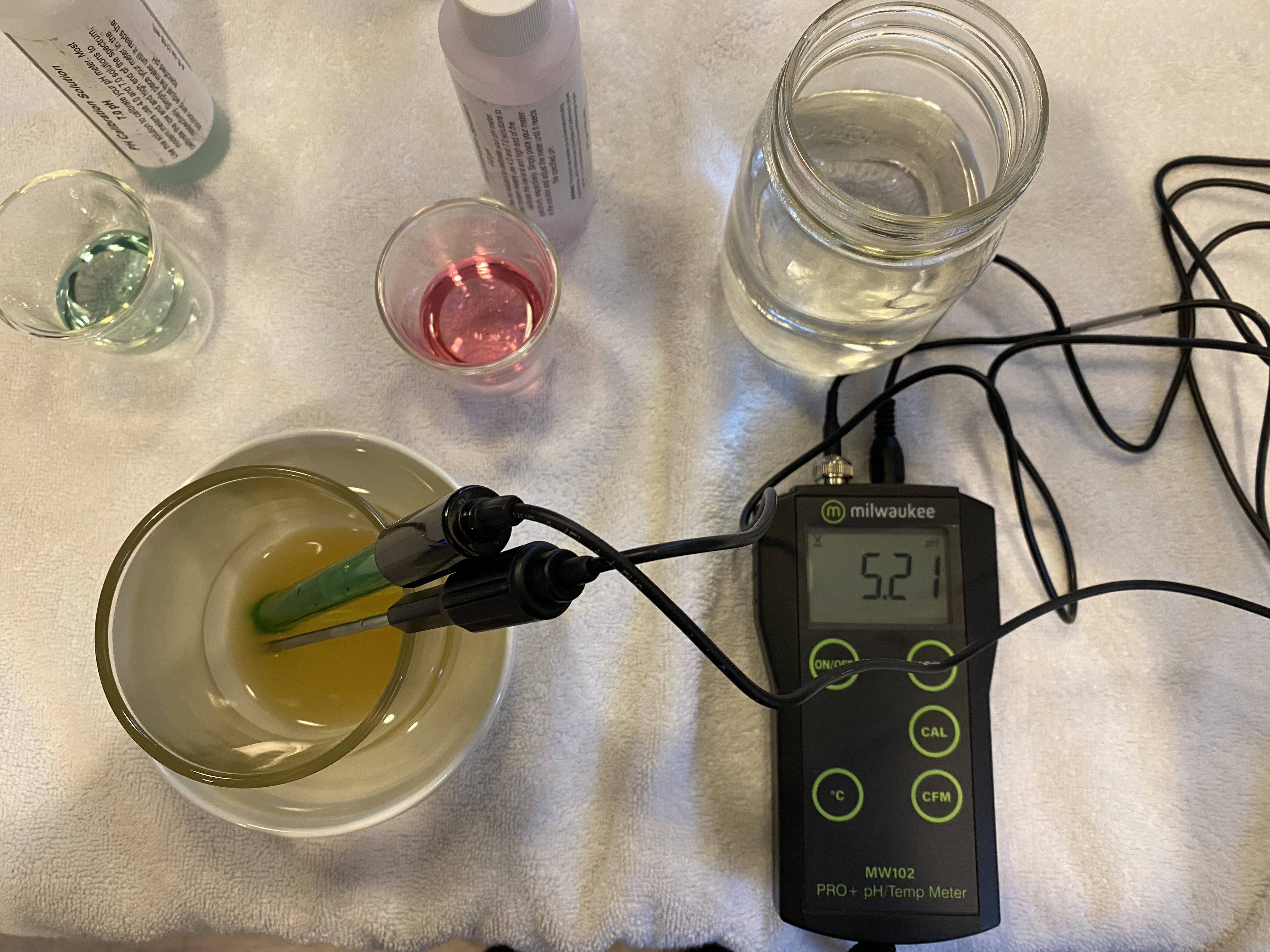

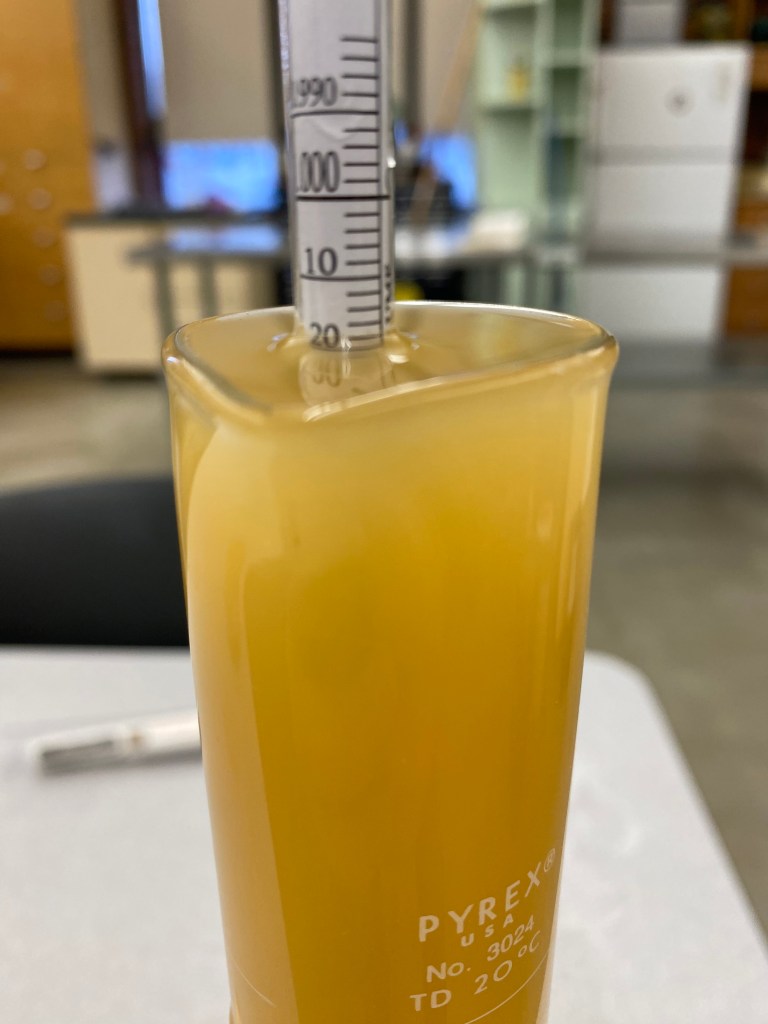

January 21, 2023 – Cold Lager Batch

The day prior to brewing, I collected 10 gallons of RO (reverse osmosis) water for brewing with. I started the day by heating up my strike water for my mash. While the water was heating, I measured out my salts and milled my grain. Once the water was up to temperature, I added my salts and then the milled grain slowly while stirring. After it was all stirred in, I checked my mash temperature and it was at my intended 152 degrees F. I let it sit for about 10 minutes and then started recirculating the wort through the mash to maintain my target mash temperature. At the end of the 60-minute mash, I increased the temperature of my Brewzilla to 168 for a mash-out, while performing a vorlauf to clarify my wort. Once I reached mash-out temperature, I pulled out the grain basket to drain into the kettle. I fly sparged with 170 degree F water until I hit my desired pre-boil volume. Once my wort hit a rolling boil I added my hops at specified times. The wort was quickly chilled with my immersion chiller post boil. I then transferred the wort into a sanitized fermenter and set the temperature to 55 degrees F using a glycol chiller. Once the wort was cooled to this temperature, I pitched the lager yeast that I had harvested from another batch of beer. This batch fermented at 55 degrees F for 6 days before increasing the temperature to 65 for a diacetyl rest. Two weeks after the brew day, I did an oxygen free transfer into a sanitized and purged keg to lager at 32 degrees F.

February 4, 2023 – Warm Lager Batch

On the same day that I packaged the cold lager batch, I harvested the yeast to use for my warm lager batch. This batch was brewed at my home, unlike the previous batch brewed at CWU. While I was away getting the supplies needed to brew this beer, I had my RO water heating up in my Brewzilla. Note: I was unhappy with the final gravity of the previous beer and I decided to lower my mash temperature to 148 because these beers were not only for this class, I also planned on entering one of them into a competition, and I wanted a beer that had a lower final gravity. Once I made it back home, I weighed out my salts to add to the mash water. I incorporated my grains into the water in the same way as my previous batch. The grain type and amounts did not change. I recirculated the wort through the grain to maintain my desired mash temperature and at the end of the 60-minute mash rest I increased the temperature to 168 degrees F for a mash-out. I fly sparged until I reached my desired pre-boil volume. This is where I had realized my mistake, I went to weigh out my hops and I had forgotten the bag of Liberty hops in Ellensburg, and I was not going to drive 2.5 hours again to go get them, so I had to improvise and hopefully reach the same IBUs and similar flavor with the hops I had at home. Hops were added according to the recipe. I quickly chilled the wort post boil and transferred it to a sanitized fermenter. I placed my fermenter in the fermentation chamber set to my desired fermentation temperature of 66 degrees F and once the wort temperature was stable I pitched the yeast that was harvested from the first batch. Seven days later, fermentation activity had slowed significantly, but I waited until 12 days post yeast pitch to cold crash the beer to 32 degrees F. On February 20th, I sanitized and purged a keg, and then added 10mL of Cellar Science Silafine to the keg. I purged the keg an additional 5 times to avoid any potential oxidation. I added finings to this warm fermented lager to expedite the clearing time that would normally take 1-2 months. I burst carbonated this beer at 50 psi for 18 hours before reducing to serving pressure of 12 psi. I conducted triangle tests of both beers on March 9, 2023.

Results

I had intended to serve these two beers in a triangle test to a panel of tasters at school one week after kegging the warm fermented batch, but I was unable to. So instead I had my girlfriend serve me 5 blind triangle tests of these two beers. I was correct 2 out of 5 times. Not quite a significant result. Before the triangle tests, I was tasting these beers side by side and they tasted very similar, but I thought I could perceive a difference in bitterness (which is understandable considering I used different hops). Once I was blind to which one was which, I could not tell them apart as easily. I thought I tasted the bitterness difference in the triangle tests, but I ultimately had to guess, and I was wrong more than half the time.

When taking my original gravity for the second batch, I realized my efficiency had dropped. I wondered if it was due to my different sparging technique. The first batch I brewed at CWU, I had a hot liquor tank and was able to maintain a nice even shower of sparge water on the grain bed using a pump. When I brewed the second batch at home, I did not have the same equipment and could not maintain a proper fly sparge technique. I suspect this is the cause of the difference in original gravity for each beer.

I intended to take more pictures but here are some I took from my two brew days:

Conclusion

Even though these beers were fermented 11 degrees F apart, used different hops, one cold conditioned for two weeks longer than the other, and different starting and finishing gravities, I was unable to reliably tell them apart in a triangle test. Maybe I have a terrible palate, which is completely possible. But I could not find any clues of what some may suspect a warm fermented lager might have. Both beers had clean fermentation characteristics and a nice cracker/bready malt flavor. The warm fermented batch cleared up quite well after only being conditioned for two weeks, although the cool fermented beer may have just been cloudy from its trip in the car back home because I remember it being clearer back at CWU when sampling.

Future Work

I would like to perform this experiment in the future with a tighter control on the variables so I can isolate the variable of fermentation temperature better. A more commonly used lager yeast strain may be a variable that I would change. A tasting panel of 20 or more would also be ideal, I honestly do not think this experiment was done as well as it could have been. Ultimately, I am willing to brew lagers now at ale temperatures to help expedite the time from grain to glass, but I would like to attempt this experiment again before I trust the results.