Hello, my name is Ken Tinseth and I am a craft brewing certificate student at CWU. I first became interested in brewing beer while spending several months in Hagerstown, MD on business. I had recently become very interested in craft beers and being raised in the NW enjoyed many beers from classic craft brewers such as those from the Widmer Brothers, Deschutes and Portland brewing (now closed). When I was in MD I enjoyed many beers from Dogfish, Ommegang and Flying Dog which further peaked my interest and opened my eyes to the wonderful world of craft beers. Along the way someone mentioned the home brewing process and from then on, I was hooked. When I eventually returned home I set up my first home brewery. This home brewery was a gas fired, single kettle system where I mashed and batch sparged using an insulated cooler. This worked great for several years but then it was time for me to move and with that move came an opportunity to change it up a bit.

Lessons learned, from the the first home brewery, were that I wanted an electric system that allowed greater control of temperature and did not produce the excess heat and particulates that the gas fired systems produced. I also wanted the option to brew 10 gallon batches and to pump the wort vs relying on gravity transfers. I settled on a Blichmann 10gallon Electric RIMS system.

During this practicum I elected to do the following:

- Set up an all electric brewery and perform a trial test run (using only water) on this system prior to brewing.

- Perform an initial test brew on this system and determine brew house efficiency.

- Brew a 10 gallon evaluation batch of a modern take on a Belgium Saison.

- Divide this batch up equally and ferment one batch at 65-75 and the other at 75-85, always keeping a 10 degree F difference between the two. Both batches using the same yeast (Belle Saison dry yeast)

- After fermentation and conditioning, determine if there was a noticeable difference in the flavor profile between the two beers and if so which one is more desirable.

As of May 7, 2023 this is the status:

The set up and trial run is complete. Several issues such as 2x30AMP power requirements for electric system, layout of room, work flow, ingredient storage, water supply, and water analysis were all evaluated and room/equipment was designed and built/installed. Also a trial run using water only was conducted to become familiar with the system and to test for leaks and other issues prior to brewing the test batch:

Acquired all ingredients necessary:

Test batch to evaluate brew house efficiency was brewed and the brew house efficiency was determined to be around 75%. Then the 10 gallon evaluation batch of saison was brewed:

Divided 10 gallon batch in half and fermented at different temperatures. Higher temperature batch with heater belt attached on left and lower temperature batch on right. Note difference in color after two weeks of fermentation:

June 4, 2023 update and final report:

These evaluation beers were transferred to corney kegs, cold crashed, conditioned and forced carbonated. Samples were bottled and taken to CWU for formal evaluation using a standard triangle test at the sensory lab by the Craft Brewing Sensory Analysis of Brewing class on June 2, 2023. Below is a summary of this project:

For me this project was about bringing this past academic years studies, in the Craft brewing program at CWU, all together. It gave me the opportunity work with all the challenges of putting together a small brewing operation from the ground up. Then I was able to use what I had learned from the various Craft Brewing classes such as biochemistry and micro biology of brewing, Hop science and sensory analysis to brew a specific style of beer and to understand why/how each step is done, how it effects the beer and how changes to those parameters might effect the final product.

During this practicum I was able to complete all the items listed in the initial proposal above. It was meant to simulate a real world scenario where a brewery, trying to tweak a recipe/process of a beer/brewing operation, brews a beer, changes some thing about it and formally evaluates the final product. Whether it is to save on heating/cooling costs, ingredient costs, create efficiencies or to improve the taste of a beer, the process is very similar.

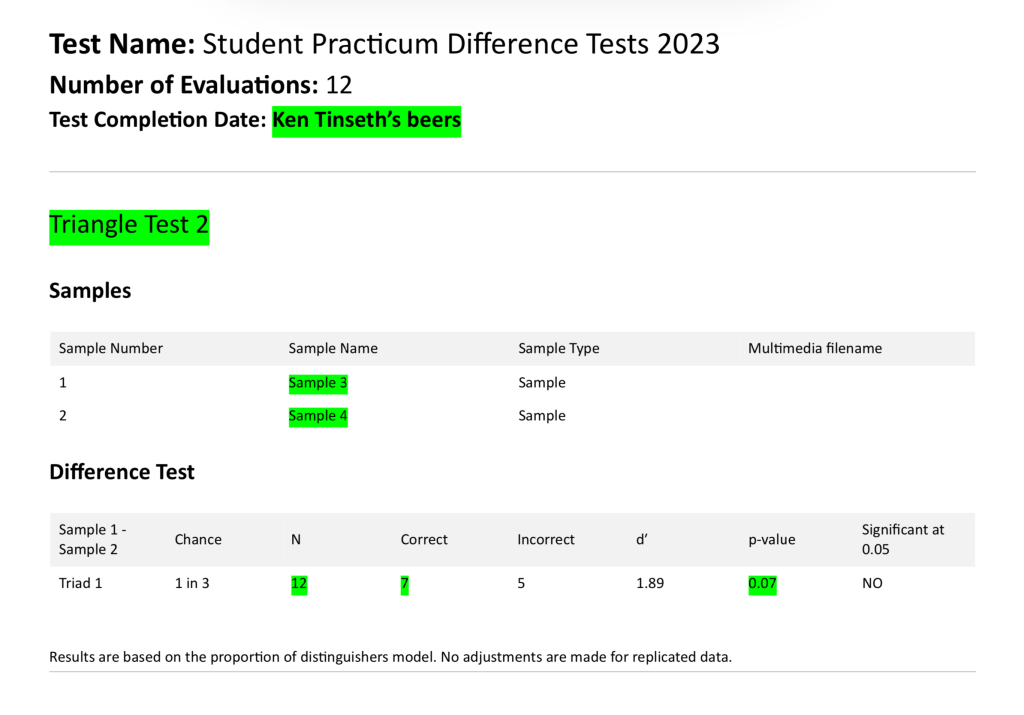

The final sensory of analysis of these two evaluation beers seems to be somewhat inconclusive. A p-value to determine significance was set at .05. This evaluation yielded a p-value of .07, indicating that there was no difference in the taste/aroma of these two beers (see data below):

Based on the p value being so close to the .05 threshold of significance and the small number of judges (12) it would be prudent not base any major decisions on this evaluation but instead re-evaluate the 2 beers using a larger number of judges. However, using this data and my analysis of this beer and style that I am intimately familiar with, personally I would probably elect not to utilize the additional electricity required to maintain this fermentation temperature at 85 degrees nor would I utilize the energy required to lower the temperature down to 75. Instead I will probably set 75 F as the low end and let the temperature rise naturally into the mid 80’s during fermentation and then let it settle back to 75F. I can do this now because I feel the temperature range evaluated (75 and 85) produced very similar taste and aroma profiles for this specific style and yeast (Lallemand Belle Saison).

In the future I will continue to use this technique to brew personal flagship beers and tweak parameters and then evaluate the results. This particular evaluation was done after the hot side (pre fermentation). In the future I hope to become proficient enough with my system to be able to brew two identical beers while making slight changes to the hot side and then evaluating those results.

Cheers!