Hello, My name is Austin Haase and I am currently a senior here at Central Washington University. I will be graduating with a Bachelors of Science of Biology with a Specialization in Biomedical Sciences, a Chemistry Minor, and a Craft Brewing Certificate. For my spring practicum to obtain my certificate, I wanted to start with the basics and do my first ever home brew. Being German myself, I wanted to do a German style beer. However, being a STEM major also involves maybe being a little bit too ambitious.

Historical Context:

Germany is certainly known for its unique characteristic of brews. Primarily the lager, which is bottom fermenting, that has taken over the country. However, dozens of other top fermenting beers were once popular throughout the area. Those who carried on the tradition post WWII have keep certain brew recipes alive like the Gose and certainly the Lichtenhainer. This beer is characteristically brewed with smoked malt, light hops, and purposely inoculated with lactobacillus to make a weak sour beer. Preferably served young, this beer is a smoked sour German Weissbier or “wheat beer”. It is most commonly brewed in Thuringia, Germany. Since this beer is meant to be served young it worked out for this quarters scheduling and is not meant to be very high in ABV, around 3.75%!

Starting the project:

Since I wanted to home brew beer on my own once I graduate, I went ahead and purchased my own home brew kit. The brew kit alone comes with the majority of the supplies and includes a kettle, fermenter, testing equipment, and other various quality of life tools. Since the Lichtenhainer is traditionally a Weissbier and the kit comes with a Hefeweizen brew kit, the American version is being cost effective and using the Hefeweizen brew kit to make the beer, inoculating it to sour it, and then using a smoked malt for the wort.

Tentative recipe:

For this project I followed an online recipe from HomeBrewAcademy.com by Steve Thanos. This was apart of his 99 beers in 99 weeks series. This post also gave specific numbers expected from this beer and what we should shoot for when brewing and souring.

We started out this project with having 3lb smoked barley malt (mesquite), 6lb of wheat malt extract syrup, 1lb of DME (Briess golden Light), and lots of Munich base malt. Before we started brewing, following the recipe, it called for 3lb smoked wheat malt, 3lb pilsner, and 1.5lb Munich base malt. However, with the ingredients that we had, we opted for just 3lb of milled smoke barley malt, and 1.5lb milled Munich for base malt.

Protocol for Brew Day: (April 27, 2023)

1. Sanitize and Preparation

- Thoroughly clean and sanitize ALL brewing equipment and utensils with Star San for 5 minutes.

- Place the malt extract syrup bottle into a container of warm water to help transfer it to the boil later.

- Install spigots onto fermenter and test for leaks.

2. Mashing Grain

- Mill the smoked barley malt (3 x 1lb bags).

- Pour ~ 3 gallons of clean pre-warmed water into a kettle: Total water: 3 gallons.

- Heat water until (152° F or 67° C).

- Add milled barley and Munich base malt to the kettle and mash for 60 minutes, stirring occasionally.

3. Measuring and Adjusting O.G.

- Heat another gallon of hot water and sparge the grain into the electric kettle.

- Total Water: 4 gallons- bring to boil for 15 to stop enzymatic activity.

- Add wheat malt extract syrup ~ half of bottle (3lb) to start adjusting to 1.038-1.056 specific gravity.

- Add clean water until the 5-gallon mark is reached ~ 1 gallon

- Total Water: ~5 gallons

- After O.G. is in range using algebra to adjust for the additional water, boil the mixture for 15 minutes to pasteurize it.

Protocol for Kettle Souring/ Fermenting: (May 1, 2023)

4. Cool Wort Down/ Transfer/ Kettle Sour

- Chill wort down quickly till (95° F or 35° C) using a external water chiller- the wort should still be in the kettle.

- Measure pH and add acid blend (preferably lactic acid) until wort is equal to 4.5 pH or less.

- Pitch in the lactobacillus bacteria, and cover to reduce any oxygen (maybe swapped with previous step if no pH adjust is ideal).

- Sour for 1 day at (95° F or 35° C) or until pH ~ 3.8. monitor very closely (possibly hourly).

- Once souring is done, bring back to a boil to pasteurize and kill the lactobacillus bacteria.

(Date souring is done May 2, 2023) (07:00 TIME)

5. Hops and Fermentation (Date 05/04/23)

- Add hops (clean hops – little aroma, just need bitterness) and boil for 60 minutes to bitter.

- Take the final-original gravity.

- Cool rapidly again with another water chiller to (68-71° F or 20° C) and transfer sour wort into fermenter with sanitized tubing.

- Pitch yeast into the mixture/ stir well with sanitized spoon or shake/ securely fasten lid

- Add the airlock on top and fill it halfway with Star San.

- Place into a temperature stable environment and ferment at (68-71° F or 20-22° C) for 1 week or until bubbles stop forming in the airlock.

- Take F.G – bottle beer and bottle condition or infuse with CO2.

1st Practicum Update:

For this update, the previous instructions were developed before we started brewing and slightly modified after brewing was done and the beer was fermenting. This section is an explanation of what we did while trying to follow the instructions made. First off, we started by washing out and sanitizing the kettle with Star San.

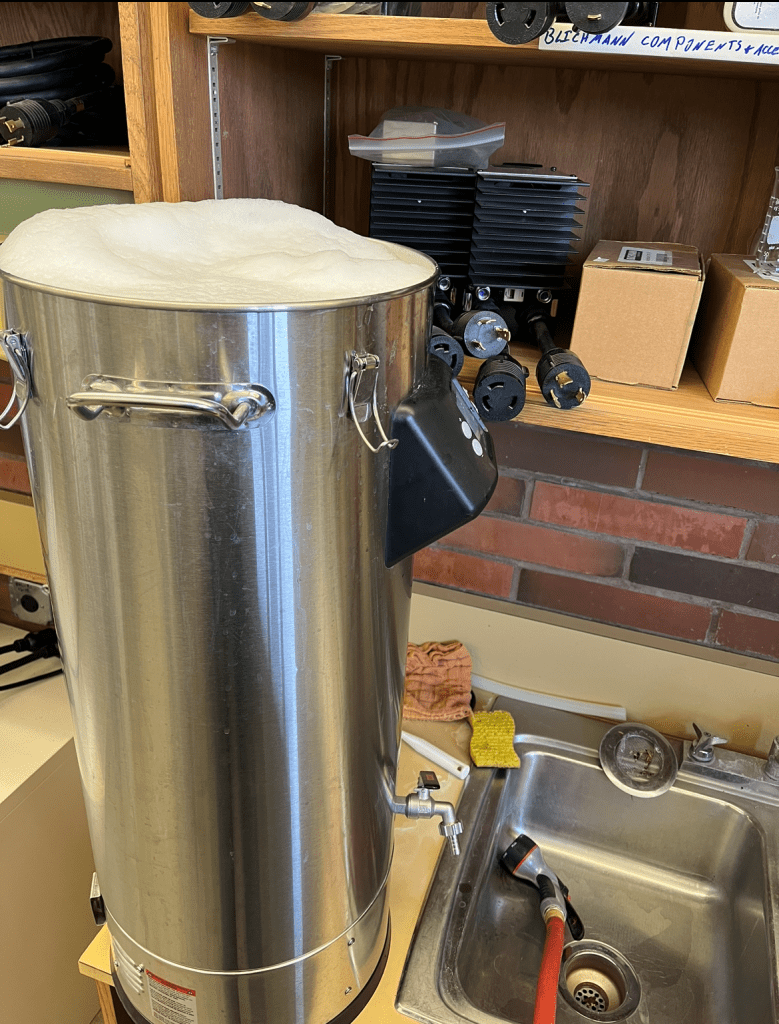

At this point, I only purchased a metal pot kettle but we needed to sour the beer at 95 F for a long period of time and need precise control of temperature. So we borrowed a donated kettle from last practicum to mash the wort and kettle sour.

While we let that sit, we milled the 3lb of smoked barley malt and 1.5lb of Munich base malt in a electric mill provided by the CWU Brew lab.

We heated 3 gallons of water in the kettle and mashed for 60 minutes, afterwards we pulled the grain strainer out and let it drip into the kettle. In the beginning of the mash, we added some rice husks in order to liquify the grain and make it easier to stir.

We sparged the grain with another gallon of water and let it all drip into the kettle. We added 3lb of wheat malt extract syrup and added more clean hot water to the kettle. We didn’t need to add any DME as the gravity was already in range after the addition. We then boiled the wort to pasteurize it and due to scheduling conflicts, we let the wort sit over the weekend, or 4 days. Unfortunately, our kettle malfunctioned and sprung a leak and we lost some wort over the weekend. We were left with 3.25 gallons. Pushing forward, it was time to kettle sour and after the wort was brought up to a boil again to kill anything, we let it cool to 95 F using a copper external water chiller. We then added 125mL of 85% FCC lactic acid into the wort. After checking that the pH was in range for the bacteria, we then added the lactobacillus wet solution of 125mL.

We finished about midafternoon and let the lactobacillus sour the wort overnight. Around 7am the next day, the pH was at 3.71 which is just in range, and we brought it back up to boil and killed off the bacteria to stop the souring.

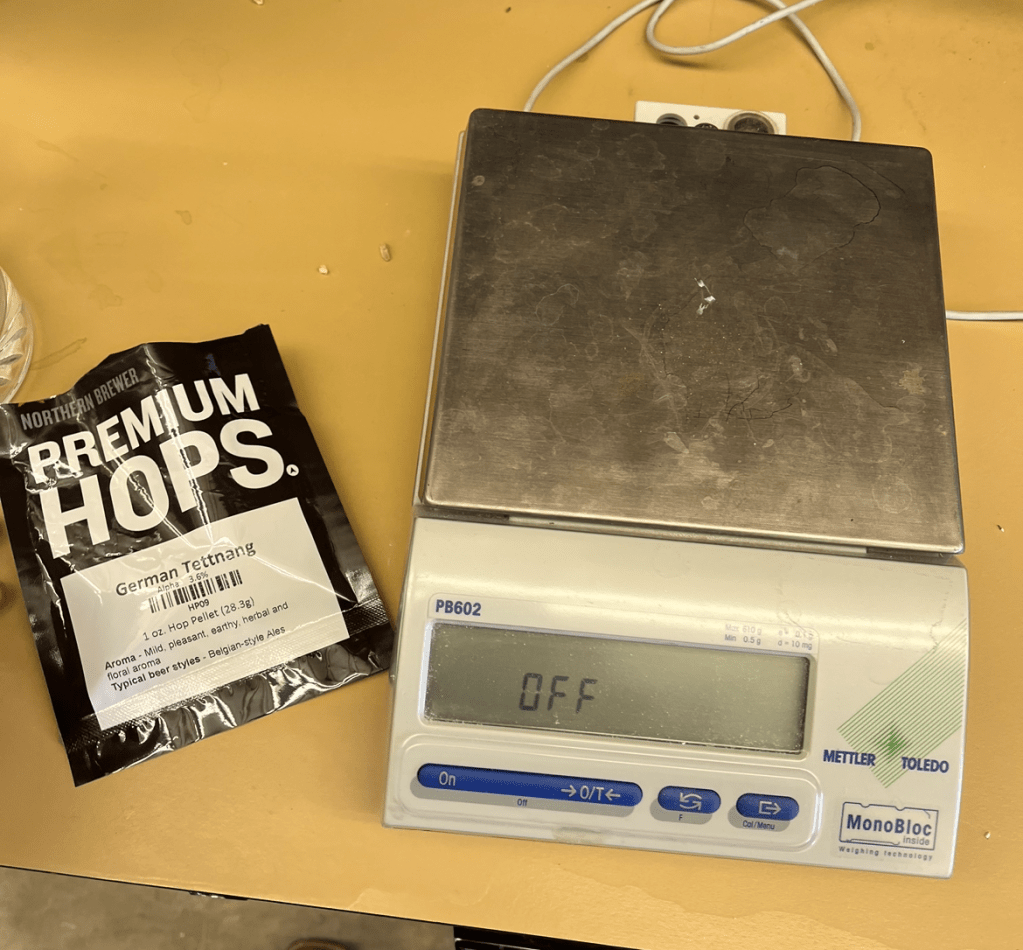

On Thursday (May 4, 2023), we had a 1oz bag of Tettnang hops from the purchased brew kit and it was meant for 5 gallons, so we determined for 3.25 gallons, we needed 0.65oz of hops to bitter the wort. We measured out and boiled the hops in a hop’s strainer for 60 minutes. Keeping to the American way, we actually had the slow roiling boil come first before we added the hops, while traditionally, the hops in German beer is added while the wort is coming up to a boil.

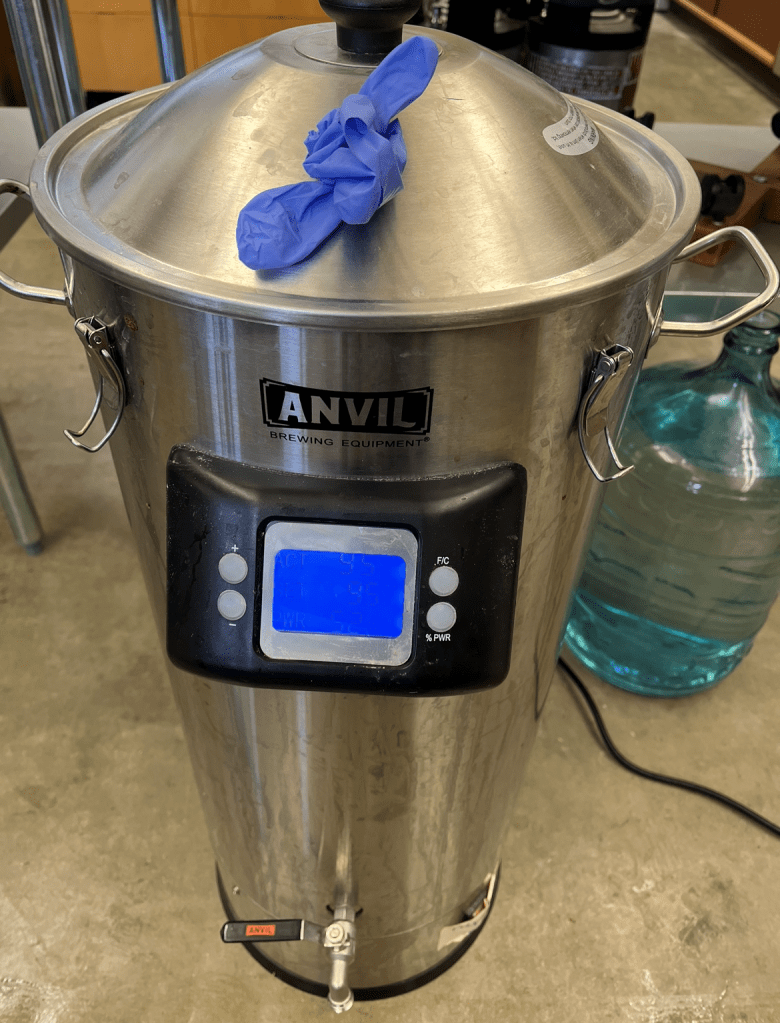

While this was going on we sanitized the fermenter with a much stronger acid than Star San. Afterwards, we cooled the wort with an internal water chiller to 71 F and transferred the sour wort into the fermenter using sanitized tubing.

We took the true OG after we added the wort to the fermenter. All measurements of Specific Gravity was done using a smart hydrometer and the reading was taken off the associated phone app. All pH readings were done using an electric pH probe. After, we pitched 8g of Cali dry yeast and mixed it in and shook it lightly. We had a package of SafeAle yeast provided by the Hefeweizen kit but it would have added flavors of clove and banana and we decided that it would go against the complex flavor profile we had already developed. So we went with the Cali dry yeast that we had on hand for its very weak addition of any flavor. We installed the airlock and filled it with Star San solution. We then locked the lid and made sure there was no leaks this time. Currently, the fermenter is working its magic and the yeast are producing gas which means its working. There is a scheduled checkup on the fermenter next Thursday, May 23, 2023 to see the progress of the yeast.

We calculated, with the OG and expected FG, and an 80% attenuation, to have about a 5.38% ABV. This is also were the Americanization comes in as, yes, the true recipe says the beer is supposed to be a very low ABV but we wanted to increase it as most American light beers are within this range. Further steps include waiting for the fermentation to finish, then bottling the beer and adding CO2. I have plans to set up a tasting event where we will ask people to come in and try the beer and let them describe the flavors they get to determine the profile of the beer without any outside influences. This is mostly going to be recruitment within the brew club and Craft Brewing Program as they already have a keen nose and flavor profile developed. Some outside responses also may help to determine what its like for someone who doesn’t drink specialty beers like this one.

Measurements:

Mash in Gravity-1.030 pH- 5.38

1st wort Gravity- 1.042 pH-5.25

Last wort Gravity-1.034 pH-5.29

Last wort + 3lb MES-1.060 pH-5.36

OG at 3.25 gallons and 125mL of lactic acid-1.051 pH-4.26

Post hops OG-1.052 pH-3.68

OG-1.052 pH-3.68

FG- ??? pH-???

Final Report 06/04/2023

My idea for this project was to brew my very first beer. I didn’t want to do anything basic, but I also wanted mine to be unique. I always liked German style beers and the process they went about brewing. I began my research for unique German style beers and landed on the Lichtenhainer. Post WWII there was a huge push for bottom fermenting beers but seldom top fermenting beer styles were kept alive and brought into the new century. This beer is characteristically brewed with smoked malt, light hops, and purposely inoculated with lactobacillus to make a weak sour beer. What makes this unique is that its a smoked sour German wheat beer and today, its commonly brewed throughout the region of Thuringia, Germany. Being a beer that is meant to be served young, have a low ABV, and certainly get the attention of a beer enthusiast, I set forth developing my proposal.

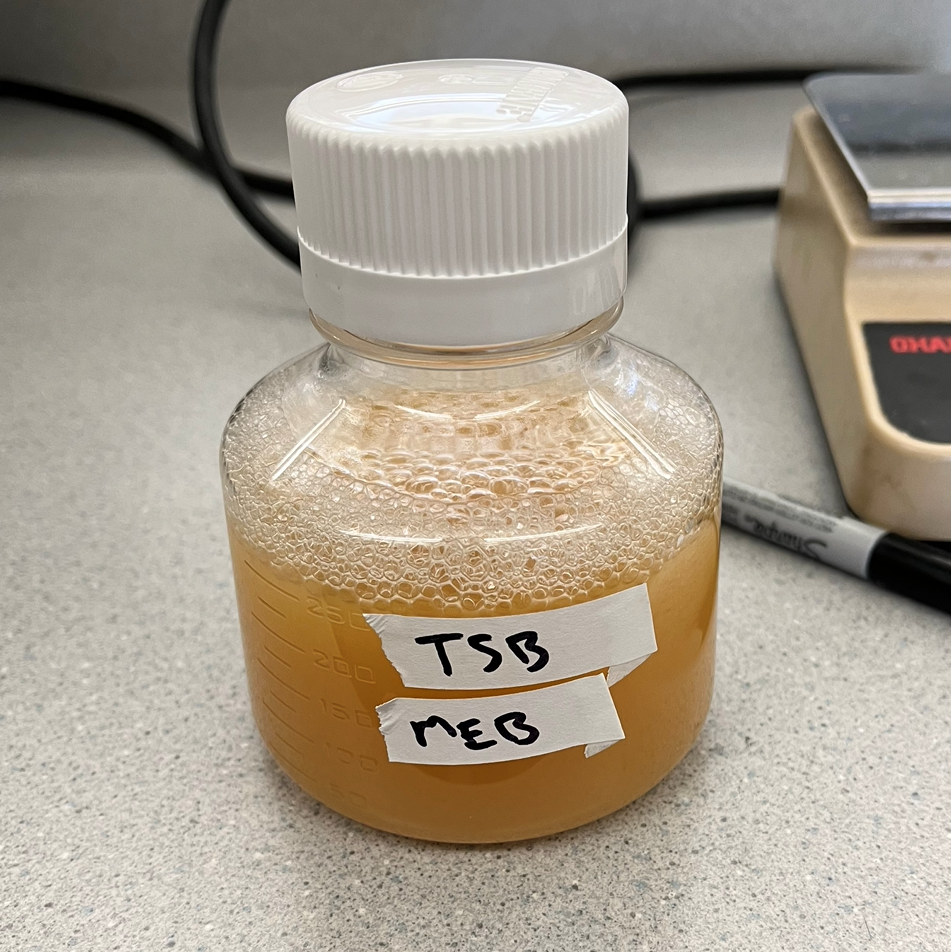

My initial proposal included me collecting all of the supplies, generating a recipe for the beer, getting signed off to do the beer, and then setting up a schedule to brew and work through the necessary steps to make the beer. Since I wanted to home brew after I graduated, I opted to purchase a home-brew kit for myself. One of the first challenges to overcome was figuring out the necessary supplies to make the wort. The kit I had bought included a free Hefeweizen kit with liquid malt extract, DME, and even hops, but I needed to convert all of that into the Lichtenhainer recipe I was using off of Homebrew Academy. We figured out that we can use the smoked barley malt that was donated to the program as the smoke aspect but we also needed a base malt. We opted to settle for 3 lb’s of smoked barley malt and 1.5 lb’s of Munich base malt for the bulk of the mash. We also used lactobacillus isolated from Icelandic yogurt that was grown in lab that we used to inoculate our beer for kettle souring. We also used a very plain yeast to ferment the beer as we didn’t want any yeast flavors to be added to the already complex flavor profile. After the initial recipe was made, I talked to my advisor and got signed off to do the project with much enthusiasm and interest which was nice to hear. Unsurprisingly, an unforeseen problem was that making beer is a major time commitment, being a full time college student, working 2 jobs, and well, basic living necessities, it was very difficult to make time for. By the time the wort was done and it had accidently leaked all over the floor over the weekend, we developed a clearer schedule as when the next step in the process was taking place. Otherwise than that we followed the recipe that I had drawn up and started by milling the grain, mashing the grain, adding the liquid malt extract until the correct OG was met, added some water here, added some lactobacillus there, waited until the pH was right, and then added the yeast and fermented it. By the end of the quarter, I had produced a viable beer with enough time to do taste testing and clean up.

For the results of this project, I tried to collect as much numerical data as I could that is highlighted above and all that was left was obtaining the final gravity and pH in order to calculate the final ABV of my beer.

OG-1.052 pH-3.68

FG- 1.016 pH-3.61

Final ABV: 4.59% Apparent attenuation: 68%

We ended up collecting about 4 growlers worth of beer even with the significant loss earlier in the project timeline. The last stretch was carbonating the beer. I knew that we could bottle condition the beer and do a secondary fermentation and wait several more weeks but I made the executive decision to just keg it and pour it into growlers. We sanitized and cleaned a Cornelius keg, poured the beer in, connected a CO2 canister to it and left it overnight to see how much CO2 would diffuse into it. The next day we were ready to bottle and I left with several growlers, finished them off, then came back for the rest of it the last week before finals and cleaned the keg and collected all of my supplies.

I would say that the project was indeed a success and we hit all of our goals. We were able to develop a recipe for the beer, collect the necessary supplies, brew the actual beer, kettle sour the beer, and ferment it. An interesting aspect that should be noted is this beer changed its flavor many times with many being unexpected. When the brew was first going it would fill the room with a very nice smelling mesquite smokey flavor and we were worried it would be too overpowering. Further along the brew time line, after the souring, the smoke almost disappeared and was now more backseat with the other flavors of toast and barley. Even the sour was hardly there though the pH was so low. It wasn’t until the fermentation had finished that the beer truly showed its final flavor profile. Comments from my advisor and myself on the flavor included, a pleasant sour taste on the front that fills your mouth following by toast and barley, then the smokiness follows at the end and lingers around. Once the yeast had ate all of the sugar, the sour was much more prominent and the smoke went from the main dominating flavor to a more subtle backseat approach. I don’t want to say any personal bias, but I certainly enjoyed the taste of this beer. After several taste tests from friends, the majority of them concluded that they are more surprised by how much they like it, even though those flavor combinations wouldn’t be their first choice. I think this is an excellent observation and could be expanded on if this beer were to be made at another point in time.

For future work, setting up a real blind taste test would be a start to collect data on the flavor profile. I think open conversation about the beer is also important as that’s how it would be traditionally served in a bar and not by someone who’s blindfolded or from a marked glass 1-10. The beauty of this project is that I have the recipe already made and can easily print it out and recreate it. I also was able to develop key experiences from this class that I am able to apply to the real world. The process wasn’t perfect, but I think that’s the main point of brewing, it’s very hard to exactly recreate a beer. I think that having experiences were things go wrong is much more beneficial than it going perfectly. I now know what to expect and what to do if something like this ever happens again. In the future, I would want to actually learn to wait and bottle condition my beer and see how it ends up being after the 2nd fermentation. I want to thank the CWU Craft Brewing Program for a great quarter to send me off as this is my last quarter in college ever. Thank you and Cheers.