At the end of the last post I was talking about kegging if “it all went well,” which “it” did, becoming terminal on schedule and without any major off flavors. In this post I’m going to go over the packaging, conditioning, and sensory analysis process. You can read about the recipe research and brewing here.

This beer was by far the most hopped ale I’ve brewed thus far. All in all in my 5 gallon batch I included 3 oz of Simcoe, 1.5 oz of Cascade, 1.5 oz of Loral, and 0.5 oz of Mosaic, for a total of 6.5 oz of hops. Although this doesn’t sound like a whole lot, when it came to kegging my batch it proved to be an absolute nightmare.

In an effort to reduce exposure to oxygen we set up a closed-loop system where CO2 was pumped into the fermenter as green beer flowed into the corny keg. In principal this sounded good, and it is for shelf life, but it became a frustrating experience when the lines were constantly clogged by hop debris, forcing me to use the CO2 tank to flush the lines so that kegging could continue. Just when I thought things were flowing again it’d become clogged once more, and I estimate I lost about 1.5 gallons of beer when clearing the lines. I definitely want to look into a better way of doing this next time. You can see how much trub is sitting at the bottom of some of these containers.

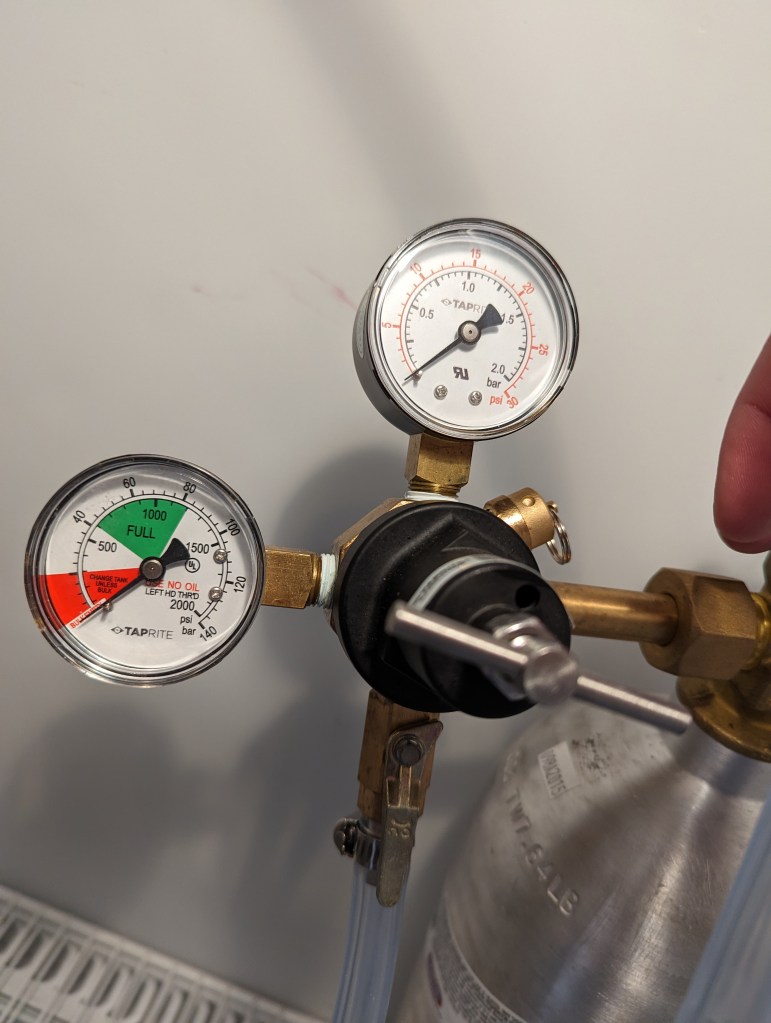

Eventually my batch was kegged, and it was time to condition. The green beer certainly tasted green considering the amount of suspended hops in the solution, and I was planning on doing tasting in a week’s time. I took the keg home and hooked it up to my CO2 tank in my (aka my landlord’s) spare fridge in the garage. My previous batch on the right was nearly empty, so it was perfect timing to swap my CO2 lines since my regulator only allows for a single connection.

After a little under a week of conditioning time, about 6 days, I started the process of bottling some samples for triangle testing the next day. Any homebrewer is very familiar with the process of cleaning, rinsing, and sanitizing bottles and lines for bottling day, so I set up a comfortable spot in my yard and got to work.

I cleaned my bottles in Powdered Brew Wash, rinsed them out, let them soak in StarSan for about 5 minutes, and then set them on the rack to dry. Ready to bottle, I went to my keg and experienced one of the most frustrating things: an empty CO2 tank. Over the last few days while my batch was conditioning I’d swapped the CO2 line over for carbonation, and I carelessly hadn’t checked on it in about 24 hours, and of course during that time the tank ran dry. This meant although my bottles were ready I couldn’t actually extract any beer from my keg. Luckily a welding supply store was only minutes away, so I dashed over for a tank swap.

This set me back because I had to wait for carbonation to build, so although my tank was refilled I wasn’t able to start bottling yet. Despite only having 24 hours until triangle testing, I had to wait. I had to head to work, so I decided to check on it that evening when I got home, and if it wasn’t ready I’d just bottle in the morning. Luckily, 7 hours later when I got home, upon tasting, it seemed ready, so I got to bottling. Ideally I think I would’ve given it another week to condition, but I unfortunately didn’t have the time, and you can see the unclarified result in the next photo.

I re-sanitized my bottles, and in the dead of night packaged a few. After hundreds of previous experiences bottling beer I finally broke my first one. That’s how it goes sometimes; you’re on a timeline and you create a mess. Previously I’d only done bottle conditioning, but on this occasion I was bottling carbonated beer directly from the keg, which definitely introduced waste as the beer flowed over as the bottle filled. In order to reduce the amount of oxygen in the bottle I had to allow the foam to spill out, so this is something I’d like to limit next time.

With plenty of beer ready for the triangle test the next day I was set. I slept nervously wondering if the participants would have any problem distinguishing my beer from the original Field 41. The next afternoon I entered the lab and helped set up the test. I poured the original Bale Breaker into the pitcher on the left, and my batch into the pitcher on the right, and immediately I could tell that the color of mine was a little more pale and didn’t quite have the depth of amber that was found in Bale Breaker’s version.

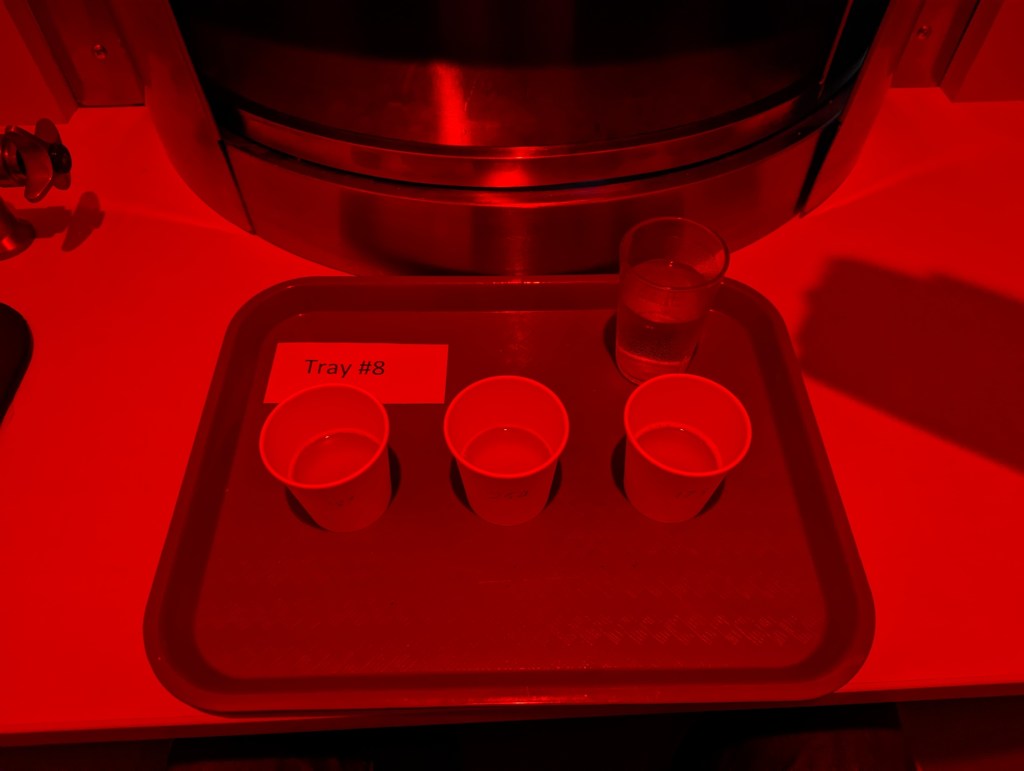

Fortunately, this triangle test was a taste test and not a clarity test, and the clever folks behind the mechanism of this trial had thought about how our visual perception can throw off taste. Within the tiny testing cubicle you’re bathed in red light, limiting the ability to tell what anything looks like from a color perspective. It’s a little bit ominous, but effective.

The goal of a triangle test is to pick the “odd man out.” Two of the samples will be the same, and one is different. You taste each one, swishing your mouth with water between each gulp, and then tap your answer out on the nearby iPad, which records all the results. There were 12 participants in this test, including myself, and the test was administered by Dr. David Gee in the CWU Health Science building.

When I sat down for the test I was positive I’d be able to easily pick mine out, but after tasting all three I was pleasantly shocked to discover that I had to go back a few times, and I still wasn’t sure. I’d tasted a little more of a “grassy” flavor and less “fruitiness” in my batch, but it was still difficult to distinguish mine from the Bale Breaker original, and in fact I picked incorrectly, which I’m not sure if that makes me proud of my brewing ability, or ashamed of my sensory analysis ability. I swear I was trying as hard as I could to not skew the results, and I even knew what to look for. I think a panel of experienced analysists would probably result in much different results.

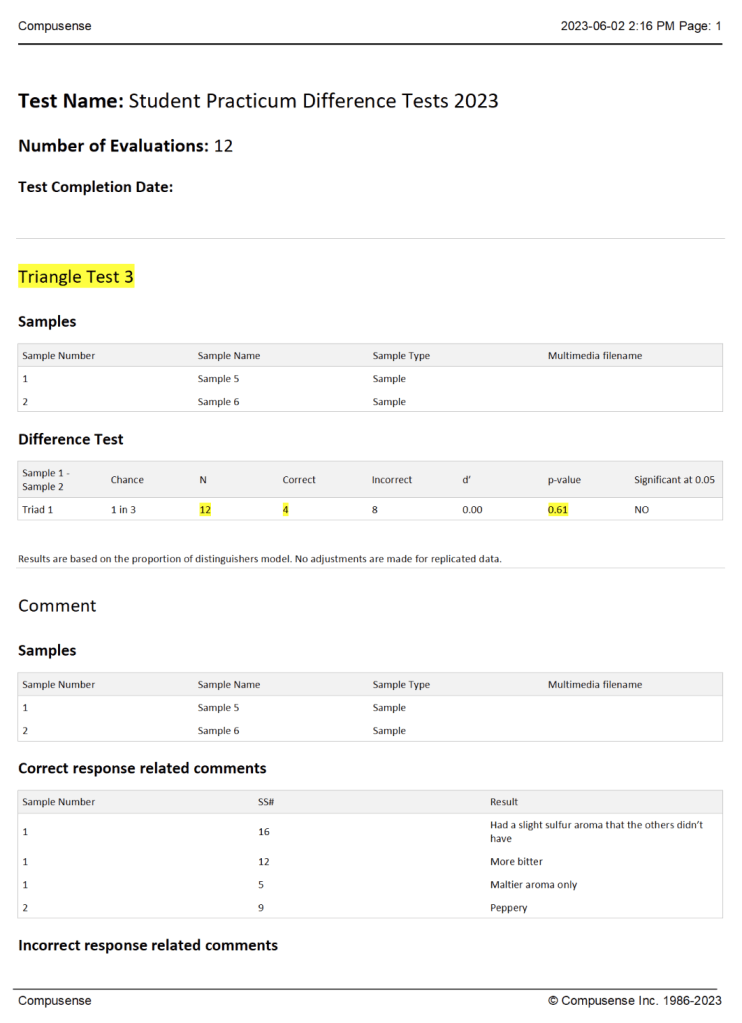

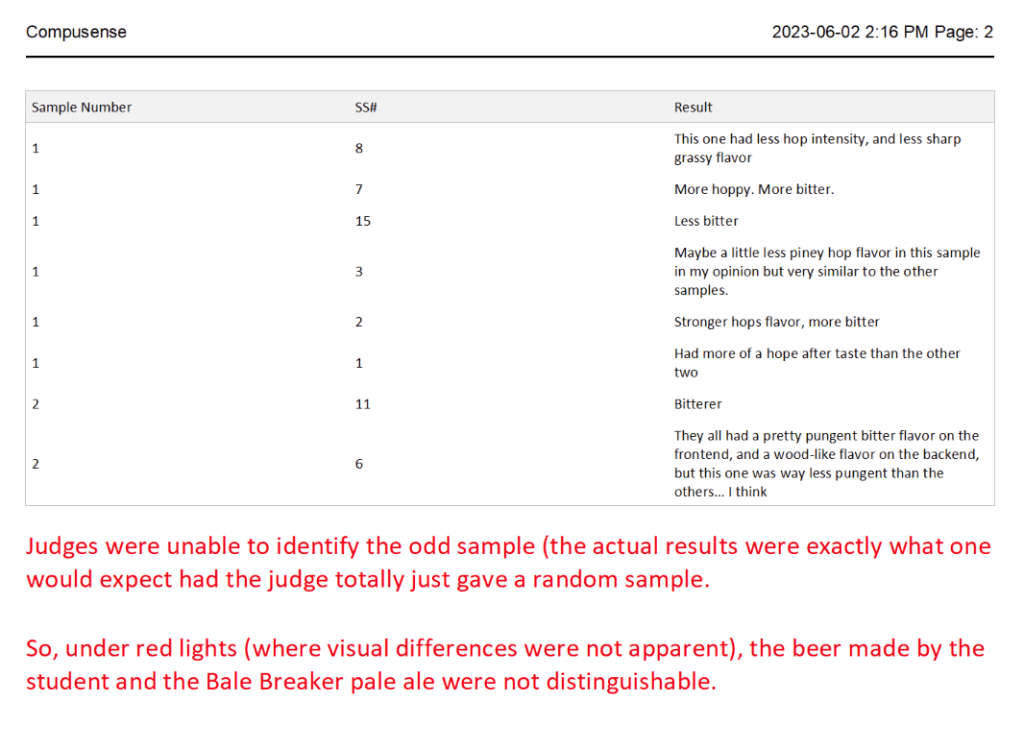

My own experience was corroborated by the rest of the participants. If you tried to pick the “odd man out” by complete random there would be a 1 in 3 chance of getting it right, and that’s exactly the results I got in this test. 4 of 12 participants were able to identify the difference between my batch and the original Field 41. To be clear, the “odd man out” wasn’t always the same beer. Below you can see more details about the test. Sample number 1 (or 5) was Bale Breaker’s Field 41, and sample number 2 (or 6) was mine.

Below, on the left is Bale Breaker’s Field 41, and on the right is my version after sitting in a bottle for a few days. There isn’t definitely a noticeable difference in flavor, but in spirit they are very similar beers. Dr. Gee told me about how light scatter from suspended particles impacts color, and since my beer clarified so much over a few days of resting it actually brought the two much closer together in appearance.

This practicum project was extremely rewarding, and I’m proud of the result. I think I accomplished my goal of creating a serviceable Field 41 clone, and I’m excited to share it with my family in a few weeks when I go to visit. I think it’ll be fun to do a tasting test with them and see if my Dad, a Field 41 tasting veteran of 10 years, can distinguish between the two.

In the future I have a few goals I’d like to accomplish. There are some noticeable flavor differences I’d like to iron out, and based on some of the triangle test comments I think there is plenty of improvement to be made in my recipe. In addition, there was a ton of waste in the kegging and packaging steps, and I’d like to iron those kinks out.

I’d like to thank Brian Logan, the Production and Quality Manager at Bale Breaker for taking time out of his busy day to share their recipe with me, and answer any questions I had. I feel so lucky to receive guidance directly from the source. I’d like to thank Brian LaBore, our Fermentation Technician at CWU, for spending hours with me during brew day, and hours after during dry hopping and kegging, guiding me and putting up with my incessant questions. Thank you to Cole Provence and Dr. David Gee for inviting me to do triangle testing, and thank you Dr. Eric Graham for creating an educational space where learning craft brewing is such a pleasure.

-Miles Koons