Hi! I’m DJ and this past summer I took part in an internship at Rueben’s Brews in Ballard as part of their packaging team at their production facility called “The Canning Line”. I had this amazing opportunity because of a few connections through scholarships which led to me meeting the owner of the Metier Brewing Company, Rodney Hines, who was benevolent enough to allow me to get connected with the Mosaic State Brewers Collective, a little later than I should have. The MSBC is a program built from a collaboration between Metier and Rueben’s, seeking to bolster the statistically low number of people of color in the brewing industry by offering internships, mentorships, and opportunities to youths who have interest in the industry.

The Beginning:

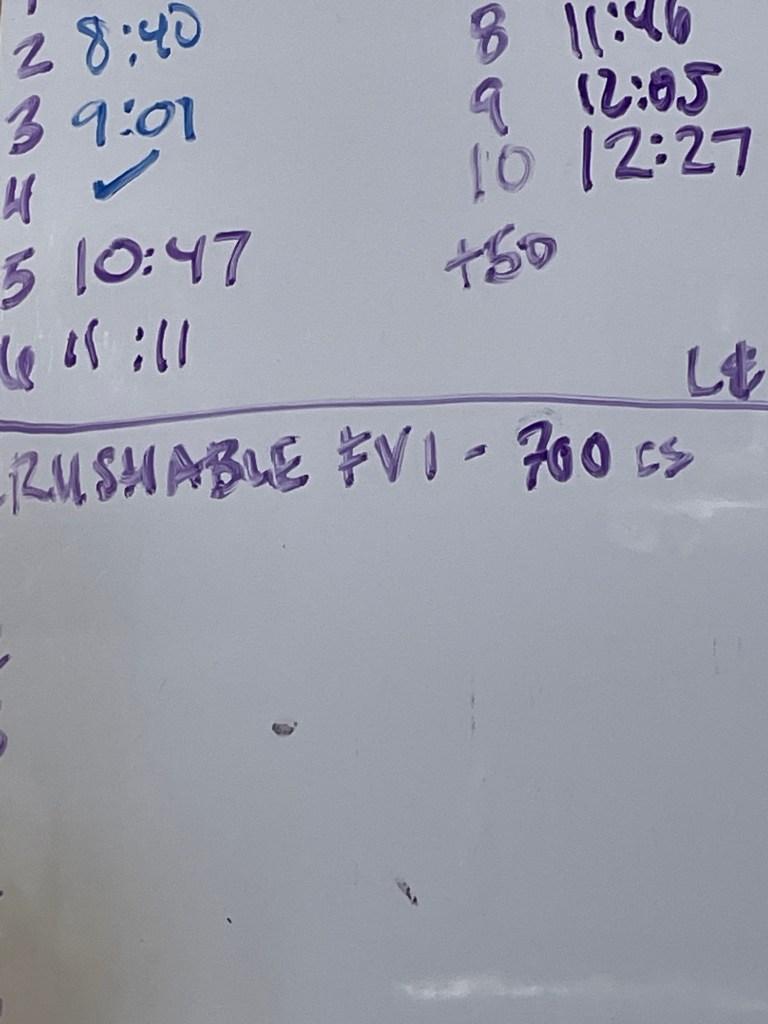

I have worked on the canning side of a brewery before, so the initial bit wasn’t getting used to something entirely new, it was more getting used to a larger scale environment. The premise is pretty simple: take six packs of cans off the line and put them into a box, 4 six packs per box, then put the box on a pallet until you have ten layers, ten boxes per layer and you repeat that until you’ve reached the target amount. Ideally the required kegs (known as 50L and sixth-bbl) have already been done before you reach towards the target amount (which you can find on a small whiteboard on the profill or through the email that you receive at the end of each day detailing what the next day will hold) because sometimes there is more or less beer than what was predicted so you want to make sure that you have enough to fill kegs and cans.

Additionally, I also became forklift and electric pallet jack certified which was something that I did not expect, but it made sense considering that its quite difficult to move pallets with about 225 gallons of beer packed on them. Something that you pick up very quickly is that malfunctions happen more often than anyone would like, so you have to know what to do during those moments of unscheduled down time. The most common activity, of course, is cleaning. From taking out the trash and recycle to scrubbing the cones of fermenting vessels, there is always something to be done for deep cleaning.

The Middle:

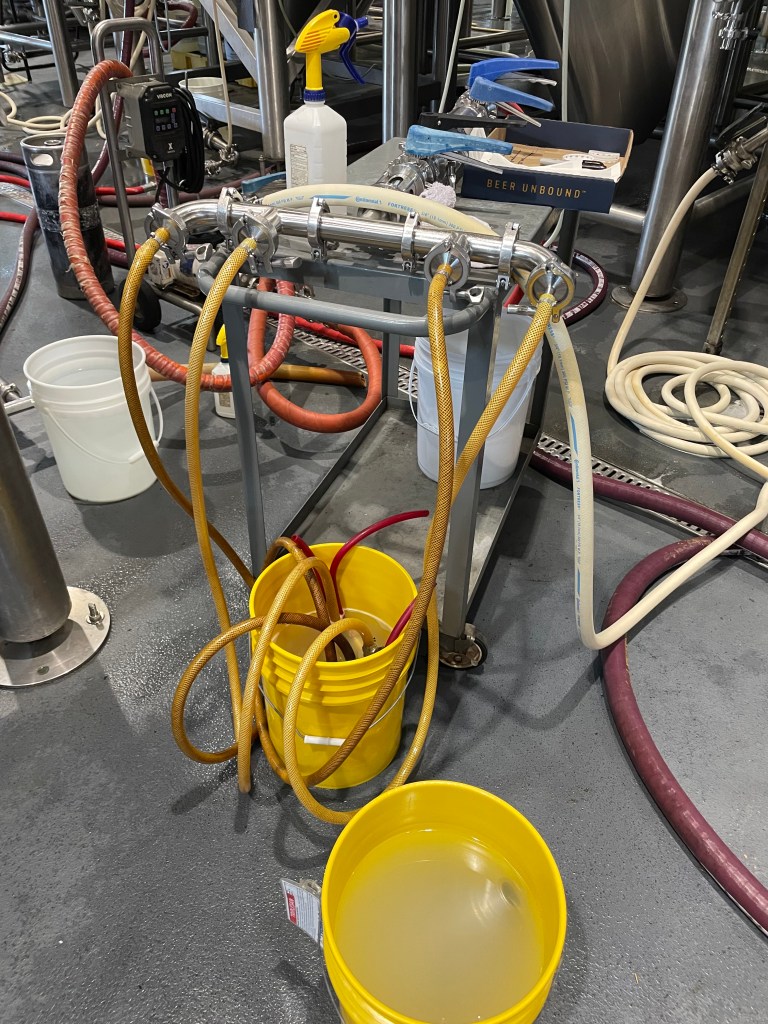

Every month, the different departments get together and have a full company wide meeting where (coupled with a presentation) everyone has a huge open floor discussion where they discuss goals, people come up with different ideas for beer, they discuss potential collaborations for the future, and anything else that happens to be on the docket. The July meeting, I had the amazing opportunity to shadow the Sales Representative, Larry Rock, who in addition to taking me on a sales ride-along, gave me his thoughts and advice as well as his business card should I ever have further questions or need some help navigating the industry. A couple things that he said which stood out to me were: “it’s important to have not just a representative from each department meet, but to have every single person involved in the discussion process to prevent departments from living in a bubble.” and “it’s important to self reflect to understand what people want and what will sell so that you aren’t making product that people won’t buy.” Sound business advice aside, I also learned that they use a nitrogen system to push liquids around not CO2

The End:

From there, it was more of the same. Besides the machinery malfunctions of course. If the canning process gets interrupted at any point that can cause a critical build of of cans on the conveyor belt that need to be put into boxes which will trigger an automated shutdown of said conveyor. Needless to say, that is not conducive towards the longevity of the equipment. But besides that, I had a wonderful opportunity to shadow a new brew lab technician! I would have preferred the senior technician (who was the person I had to beg to set up this shadow up by the way) but despite basically learning alongside me, he knew quite a bit and was as helpful as he could be. The brew lab was small but it was certainly packed with different equipment and stations. They had a station for cell counting (to determine the health of yeast being used and to decide whether or not a batch of yeast can be pitched for another batch of beer), they had a station for VDK testing for diacetyl (that buttery off-flavor), they had equipment for pH testing, gravity testing, a distillation apparatus, and even a spectrophotometer to better determine which beers could be crashed! All of this, packed into the small (and luckily airconditioned) brew lab.

After the lab shadow, the rest of the internship mainly consisted of more of the same. However, there were more and more malfunctions with the profill to the point in which it couldn’t properly fill the cans which luckily the x-ray sensor would detect and boot those cans off the line, which in this case was pretty much all of them.

Final Thoughts:

I really enjoyed this internship. I feel like this was an invaluable experience that I could never get with only classroom learning. It was great to see how this company really fit into its community, as well as some of the inner machinations of progress and logistics. I do regret how timid I was at times, those situations really prevented me from getting ahead of work tasks as I would constantly be looking for approval and confirmation that I was doing things correctly. As I was able to see, the whole process is a delicate balance and I didn’t want to risk thinking that I knew how to do something, only to find out that I had been doing it wrong and my actions have cost my coworkers and the company time and money. At the same time however, I would often feel vindicated as I would inquire further as to how and when I should be performing a task, and through that I would learn something that wasn’t initially explained to me, or was only hurriedly explained to me during an infodump. When I think about it, how could I not be timid when a single mistake could cause the loss of hundreds if not thousands of dollars down the line?

To not end on a potentially sour note, here is a picture of the largest fermenting vessel that they have, it’s so big that it wasn’t brought into the build, they had to build it pretty much as part of the building! (about 190bbl!)

Multiple times did I had the lovely opportunity to scrub the outside of that massive cone with a highly diluted caustic solution and spray it off with hot water!