Objectives

There were two objectives to my experiment. The first objective was merely to find out if my knowledge of beer creation could translate over to mead creation. Specific to this case, the creation of session mead, a lower alcohol variant that contains only 3-6.5% ABV. The second objective of the experiment was to examine the differences between raw honey and baked/dried honey in the creation of mead.

Hypothesis

Our hypothesis was thus. We believed that we would succeed in creating a session mead regardless of the type of honey used. We predicted that the meads would come out to about 4.5 to 5% ABV and present an aroma of apricot, stone fruit, and white wine grape esters. These aromas would come from the Lida Kveik ale yeast we used. We did not predict any specific aromas to come from the honey due to lack of information regarding where the honey came from or what flowers the bees took pollen from. However, we did note that this area was the most uncertain. Since aroma compounds present in honey is under researched, we extrapolated predictions based off articles from Science direct and the National Library of Medicine. Based off this data we predicted that heating the honey would cause many of the volatile aroma compounds present to denature. In addition, any glucose oxidase present would denature, resulting in a lower production of hydrogen peroxide levels and thus lower bitterness levels. Finally, heating the honey would activate any β-glucosidase if present leading to a higher sweetness and ABV in the final baked honey mead.

Experimental Design

To test the hypothesis, we made two separate batches of mead. One using raw honey and the other using baked honey using the following resources:

- Five baking pans

- Two carboys

- Water (25lbs per batch)

- Lida Kveik ale yeast

- 6 lbs. of honey, (3lbs baked, 3lbs raw).

- General cleaning/ sanitizing supplies

- Two kegs

- Eighteen bottles (bottle conditioning)

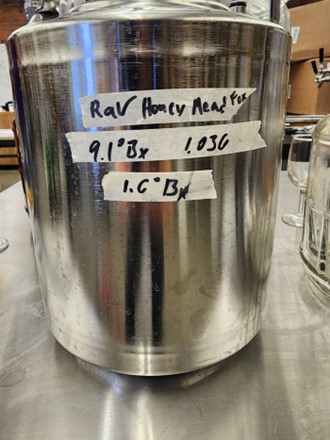

To treat the honey, we measured out 3lbs over five baking sheets. We then let them sit in the ovens for about a week before we were able to continue the experiment due to time constrains. The next week we baked the honey at about 160 degrees Fahrenheit, the activation range for β-glucosidase, for about three hours. Afterwards we used some of our warm water to loosen the honey off the sheets and scrape as much as we could into the relevant carboy to form our must (mead wort). To top off the batch, once we had all the honey dissolved in, we released the remaining ponds of water needed into the carboy and mixed by shaking. The batch of raw honey was significantly easier to work with. We were able to measure the 3lbs of honey directly into the carboy and fill with 25lbs of warm water. To finish off both meads I went and performed a cell count for the yeast to ensure its viability and determine how much we needed to pitch. We came out to 99.8% viability with 8.163 x 107 cells. Based on this data Brian then pitched 600mL of yeast into each carboy. Prior to pitching the yeast, we also measured the gravity of each, both coming out to 1.036 sg.

Results

After two weeks the meads finished fermenting and were ready for transferring and testing. Unfortunately, we did not get the ABV that we were shooting for, however the ABVs that we did get are of note. The raw honey mead came out to be 4% ABV, whereas the baked honey mead came out to 4.5% ABV. As for sensory components, the raw honey mead had a very forward floral honey and apricot aroma. The taste was lightly sweet and slightly watery, dissipating quickly. The baked honey ended with up with an earthy honey and slightly sour aroma. The body was notably tart and sweet, coating the throat for longer than the raw variant. The same remained true of both mead variants after force carbonating in kegs, however the carbonation ended up muting the aromas in both.

Conclusion

Based off the results I would conclude that the original hypothesis held true overall. At the time we took the specific gravity I was not convinced there would be a notable difference due to both coming out to the same number. However, I believe that baking the honey at 160 degrees Fahrenheit did activate the β-glucosidase and the outcome presented itself in the difference of 0.5% ABV and the increased sweetness in the baked mead. Unfortunately, I was not able to measure the glucose oxidase or hydrogen peroxide levels in the finished product due to lack of relevant measuring equipment. However, I believe it may be possible that the hydrogen peroxide levels reduced, and the lack of bitterness ended up leading to an overall tarter flavor in the baked mead. There is also the possibility that our honey became infected with a wild yeast while sitting in the ovens during the week we were unable to bake.

As for the raw honey mead, it went according to plan, coming out with the expected aromas and flavors despite the yeast being technically for ale. However, I am unsure whether it presented a stone fruit or white wine aroma because I realized after the experiment that I have not had either.

I had a great experience and was genuinely surprised to see that my hypothesis proved true. I know it was based off science, but I was not sure if the specifics would correlate in the manner that I predicted due to the lack of information on how the enzymes performed in mead. The only thing that did not go quite to plan was the ABV. It is quite possible that the yeast type or amount of honey influenced this. We are bottle fermenting a gallon from each batch, so we will see what those get up to in about a month.

Overall, I am happy with the experiment. I learned how to make mead successfully. More than that I learned just how similar it is to brewing beer. Although the materials and methods were different, we still relied on enzymes to break down higher chain sugars so yeast could feed on them. We still manipulated volatile aroma compounds both in the wort and in the yeast to create a desired aroma and flavor pallet.

Future Research Questions

Now that I know I can make mead and that using raw or baked honey does have influence, I am curious how other factors may affect a finished mead. How might the sugars in adjuncts such as huckleberries effect the efficiency of yeast? How does the raw honey used effect the mead? Does the pollen used during honey production effect the aromas present in a finished mead?